Creating safe and healthy work environments through biological safety consulting and services.

Controlled environments - healthcare, research, life science and pharmaceuticals.

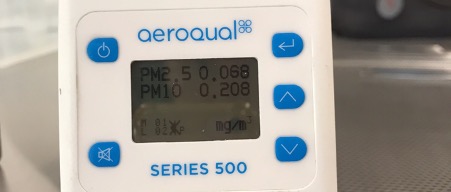

You have cleaned the lab,

how is the air?

Risks from fine particulate levels may be easily quantitated with modern instrumentation.

VOC levels from unexpected sources may be detected by calibrated hand-held monitors.

Sending immunocompromised people back into at-risk environments such as aged care and you're thinking of fogging it, you need to be aware of the chemical residues and things that may be left from the fogging process, as well as the disinfection process. Even if you're not fogging, we've had many questions around these disinfectants that claim longevity; "you know, it lasts for 30 days. It lasts for 90 days as a 90-day guarantee that it's effective against COVID-19". This suggests there is a residue left, what is the effect of that? You've got to be careful and understand your chemistry as well as the people going back into these environments, and planning and safety are the two most important things. Critical understanding; the client and people who may be going back into those places are essential to the processes you use, you may need to look at a different technology such as Chlorine Dioxide decontamination, which provides no residue after decontamination service. Pure chlorine dioxide gas does not leave a residue, as one of the first commercial uses of pure chlorine dioxide gas was for the sterilization of implantable contact lenses. In order for the process to be approved, it had to be shown that pure chlorine dioxide gas did not leave a residue.

© Copyright Biosafety. All Rights Reserved.